Top Preventive Maintenance Tools and Products for Semi Trucks

Why Preventive Maintenance Matters for Semi Trucks

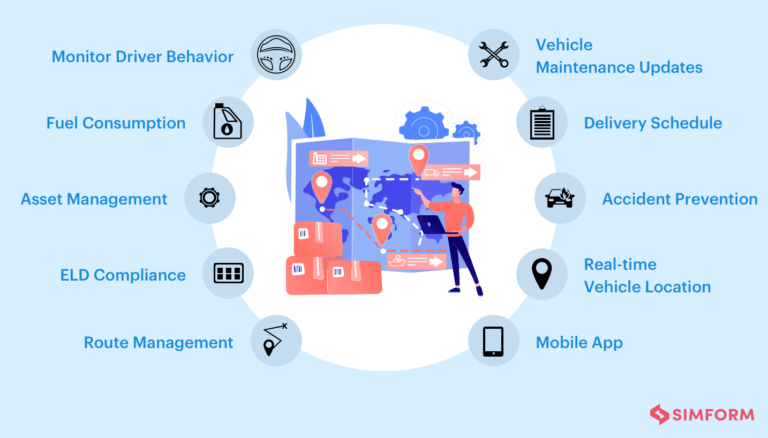

Preventive maintenance is a proactive approach to keeping semi trucks in top shape. Unlike reactive maintenance, which addresses issues after they occur, preventive maintenance aims to identify and resolve potential problems before they lead to downtime. Semi trucks often cover long distances under demanding conditions, making them prone to wear and tear.

Without preventive maintenance, fleets can suffer from unexpected failures, increased fuel consumption, and safety risks. This approach is not just about keeping vehicles on the road; it’s about enhancing performance, improving driver safety, and minimizing costly repairs.

Key Benefits of Preventive Maintenance

Preventive maintenance provides both short-term and long-term benefits that impact fleet performance and business bottom lines:

- Reduces the risk of breakdowns

- Enhances driver safety and satisfaction

- Improves fuel efficiency

- Extends the lifespan of vehicle components

- Keeps the fleet compliant with regulations

Fleet managers who prioritize preventive care also benefit from better planning, fewer emergency repairs, and improved customer satisfaction due to reliable delivery schedules.

Top Tools and Products for Semi Truck Preventive Maintenance

1. BlueDriver Bluetooth Pro OBDII Scan Tool

is a highly recommended tool for diagnostic checks. It connects to your smartphone and provides detailed reports for vehicle health.

Use Case: Helps identify engine codes and monitor real-time performance data. Ideal for fleet managers who want remote visibility into multiple trucks’ conditions.

Benefit: Saves time during inspections and prevents costly repairs by addressing issues early. Enables fast diagnostics, reducing truck downtime significantly.

2. Oil Drain Valve by Fumoto

Fumoto Oil Drain Valve simplifies oil changes by replacing the traditional drain bolt with a lever-operated valve.

Use Case: Ideal for scheduled oil changes in fleet trucks, especially when dealing with multiple vehicles.

Benefit: Makes oil drainage quick, clean, and tool-free. Reduces maintenance time and spillage, enhancing efficiency in service bays.

3. Milwaukee M18 FUEL 1/2-Inch High Torque Impact Wrench

Milwaukee M18 FUEL High Torque Impact Wrench delivers exceptional torque for removing lug nuts and heavy-duty fasteners.

Use Case: Crucial during tire rotations, brake jobs, or suspension work. It’s especially useful in roadside repairs or mobile fleet servicing.

Benefit: Reduces manual effort and speeds up repair tasks. Improves safety by ensuring secure fastening with precision torque.

4. Truck Diagnostic Software by JPRO Professional

JPRO Professional is a top-tier truck diagnostic software used by fleet professionals. It provides comprehensive diagnostics for Class 3–8 commercial vehicles.

Use Case: Best used in fleet workshops for deep diagnostics, including ABS, transmission, engine, and emissions systems.

Benefit: Helps identify component-specific issues and forecast part failures. Prevents downtime by enabling planned part replacements.

5. Air Brake Test Gauge Kit by ABN

ABN Air Brake Test Gauge Kit helps verify air brake performance, which is crucial for heavy-duty trucks.

Use Case: Ensures air brake systems meet safety regulations. Must-have for DOT inspections and routine service.

Benefit: Prevents brake failure and ensures the safety of both cargo and driver. Helps identify air leaks and maintain braking efficiency.

Benefits of Using the Right Maintenance Tools

Enhancing Safety and Compliance

Regular inspections with quality tools like brake gauges and diagnostic scanners improve compliance with DOT and FMCSA regulations. This reduces the risk of penalties and improves overall fleet reputation.

Moreover, safety inspections using high-torque tools, diagnostic software, and test kits prevent accidents and minimize liability risks. Drivers also feel more confident and secure, leading to improved retention and performance.

Reducing Long-Term Costs

Preventive maintenance tools might have upfront costs, but the long-term savings are substantial. Diagnostic tools prevent component failures. Drain valves reduce oil change costs. Impact wrenches improve workshop productivity.

Together, these tools contribute to fewer breakdowns, reduced emergency service calls, and extended vehicle lifespans—all of which add up to a healthier bottom line for your business.

Real-World Use Cases and Problem Solving

Reducing Roadside Breakdowns with Real-Time Diagnostics

Fleet managers using BlueDriver and JPRO Professional tools report fewer roadside breakdowns. These tools provide real-time fault code readings, helping mechanics address issues before a vehicle leaves the yard.

When drivers receive alerts on overheating or low oil pressure, they can return for immediate service, preventing catastrophic engine damage.

Speeding Up Service Time with Efficient Oil Changes

Fumoto valves streamline oil changes, especially during scheduled servicing of large fleets. Instead of unscrewing bolts and risking spills, technicians flip a lever and drain the oil in seconds. It’s a game-changer for multi-bay garages.

Maintaining Brake Safety in Heavy Loads

With ABN Air Brake Test Kits, mechanics can ensure air brakes function under load. This is crucial for trucks carrying hazardous or heavy freight. Identifying small leaks or pressure drops early can prevent dangerous braking failures on the road.

How to Buy These Products

Buy Now:

- Buy BlueDriver OBDII Tool

- Shop Fumoto Oil Drain Valves

- Get Milwaukee M18 Impact Wrench

- Explore JPRO Diagnostic Software

- Order ABN Brake Test Kit

Frequently Asked Questions

How often should I perform preventive maintenance on a semi truck?

Most experts recommend a preventive maintenance inspection every 10,000 to 15,000 miles, but this varies based on driving conditions, vehicle age, and load weight.

Is diagnostic software worth the investment for a small fleet?

Yes. Even small fleets benefit from real-time diagnostics. They reduce breakdowns, speed up repairs, and save money by avoiding component failure.

Can preventive maintenance really improve fuel economy?

Absolutely. Clean filters, well-lubricated engines, and proper tire inflation all contribute to better fuel efficiency. Preventive maintenance keeps all systems running optimally.

Final Thoughts

Preventive maintenance on semi trucks isn’t just about avoiding problems—it’s about maximizing performance, safety, and profitability. With the right tools and a disciplined schedule, fleets of all sizes can achieve longer vehicle lifespans, reduced downtime, and happier drivers.

By investing in quality products like diagnostic tools, oil drain valves, and brake kits, fleet managers can build a maintenance routine that ensures every truck is always road-ready.