Freightliner Preventive Maintenance Schedule The Ultimate Guide to Keep Your Fleet Running Smoothly

The Ultimate Freightliner Preventive Maintenance Schedule for Maximum Uptime

Keeping your Freightliner truck in top condition is more than just a routine — it’s a strategic investment. A well-structured Freightliner preventive maintenance schedule can save thousands in repairs, reduce downtime, and enhance fleet performance. In this article, we explore in detail how to optimize maintenance, choose the right products, and implement best practices.

Why Preventive Maintenance is Essential for Freightliner Trucks

Preventive maintenance (PM) for Freightliner trucks is not optional; it’s essential. With commercial vehicles covering long distances and bearing heavy loads, small issues can quickly escalate into expensive repairs. PM is designed to prevent this by addressing potential issues before they become serious problems.

When you stick to a consistent schedule, it reduces the chances of unexpected breakdowns. You also extend the life of the truck’s engine, transmission, and braking systems, ensuring safety and performance on the road.

Key Benefits of a Preventive Maintenance Schedule

A well-maintained Freightliner truck isn’t just more reliable – it’s also more cost-effective. The benefits go beyond simple upkeep and include significant financial and operational advantages.

- Reduced repair costs over time

- Fewer unexpected breakdowns

- Improved fuel efficiency

- Compliance with safety and regulatory standards

- Enhanced resale value

Implementing PM not only maintains truck health but also boosts driver morale and customer satisfaction through timely deliveries.

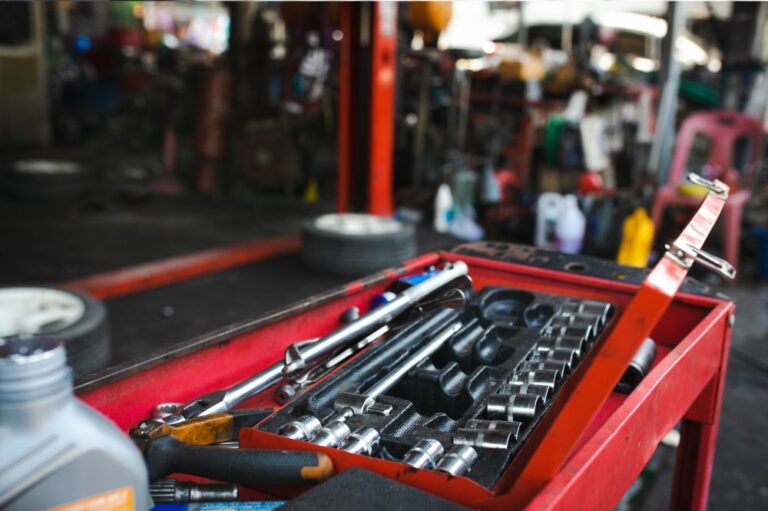

Core Components of Freightliner Preventive Maintenance

Preventive maintenance covers all essential systems in the vehicle. These include engine diagnostics, oil and filter changes, brake inspections, and electrical system checks. Here’s a breakdown of the most important components.

Freightliner Truck Engine Inspection

- Engine oil and filter: Replace every 15,000 miles or as per the model’s manual.

- Transmission fluid: Check and replace to avoid wear on the transmission system.

- Brake system: Inspect pads, rotors, and fluid levels for safety.

- Cooling system: Monitor coolant levels and radiator condition.

- Air and fuel filters: Replace regularly to ensure optimal engine performance.

By staying consistent with these checks, fleets reduce long-term expenses and maintain operational readiness.

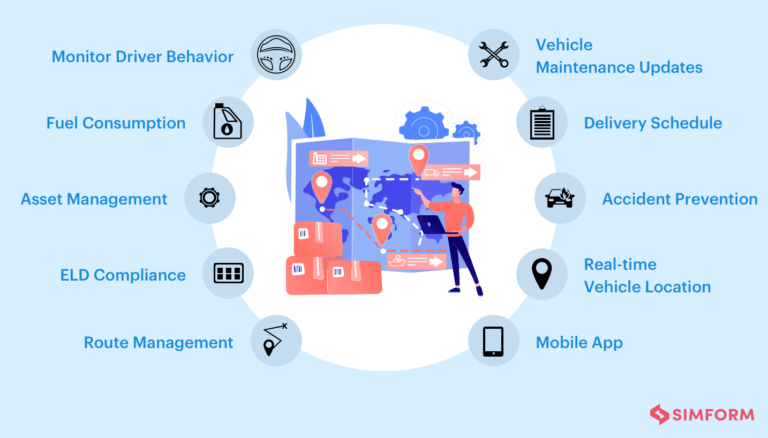

Technology Tools to Streamline Preventive Maintenance

Technology plays a vital role in keeping maintenance schedules on track. Several software tools and diagnostic systems help fleet managers stay organized and proactive.

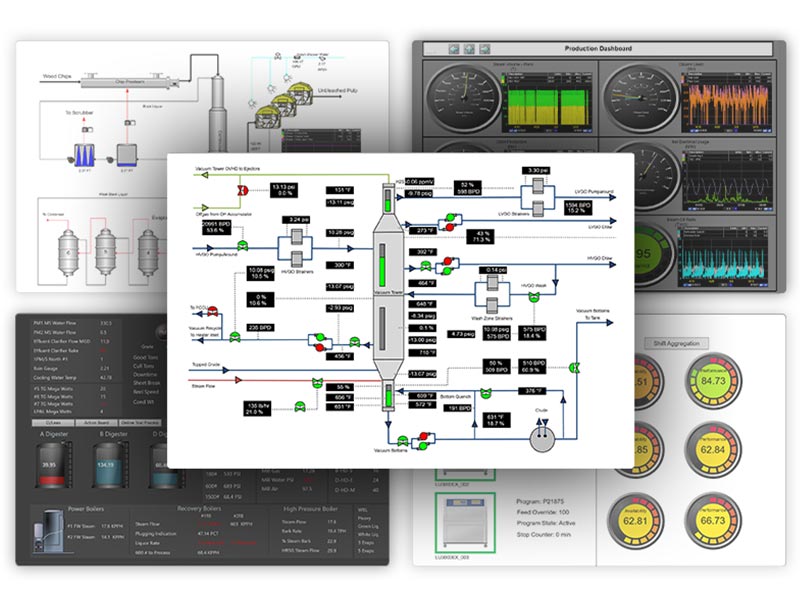

Maintenance Management Software Interface

Fleet management tools like telematics and digital logbooks automate alerts for maintenance milestones. These tools track mileage, engine hours, and error codes in real-time, making it easier to schedule service intervals without relying on memory.

Other tools use AI-powered analysis to predict potential failures before they occur. This predictive maintenance feature provides a higher level of control over vehicle performance.

Top 5 Product Recommendations for Freightliner Maintenance

1. Shell Rotella T6 Full Synthetic Diesel Engine Oil

Shell Rotella T6 is widely trusted for Freightliner trucks due to its superior engine protection, even under extreme temperatures. It enhances fuel economy, prevents sludge buildup, and extends oil change intervals.

This product is highly recommended for long-haul operations where durability and performance are crucial.

2. Fleetguard LF14000NN Oil Filter

This high-efficiency oil filter provides enhanced engine protection by trapping contaminants effectively. It’s built specifically for heavy-duty diesel engines, making it ideal for Freightliner models.

Durable construction ensures a longer service life, reducing downtime and filter replacement frequency.

3. WIX 49980XE Fuel Filter

The WIX 49980XE ensures clean fuel delivery to the engine by capturing harmful particles. This fuel filter improves combustion efficiency and minimizes the risk of engine misfires.

It also supports better fuel economy, which is essential for high-mileage fleets.

4. Valvoline Premium Blue Diesel Exhaust Fluid

Valvoline’s DEF reduces nitrogen oxide emissions in compliance with EPA standards. It enhances overall system performance and is compatible with all SCR-equipped Freightliner trucks.

Using high-quality DEF like Valvoline ensures environmental compliance while keeping maintenance costs predictable.

5. Bosch ICON Wiper Blades

Though often overlooked, wiper blades are essential for driver visibility and safety. Bosch ICON blades are durable, all-weather resistant, and easy to install.

Frequent replacement ensures safe driving in all weather conditions, reducing risks during long-haul trips.

How These Products Solve Real Problems

Let’s explore real-world use cases for why investing in these maintenance tools and supplies is essential.

- Case 1: A logistics company reduced their engine failures by 60% after switching to Shell Rotella T6 and implementing a 15,000-mile oil change schedule.

- Case 2: A long-haul operator eliminated fuel injection issues with regular use of WIX filters, improving fuel efficiency by 12%.

- Case 3: DEF usage improved compliance audits for a fleet of 80 trucks, cutting fines and downtime.

In each case, preventive measures saved thousands in repair costs and improved delivery timelines.

Where to Buy Freightliner Maintenance Products

All the featured products can be purchased online through trusted retailers:

- Buy Shell Rotella T6 on Amazon

- Buy Fleetguard Oil Filter on eBay

- Buy WIX Fuel Filter at AutoZone

- Buy Valvoline DEF on Walmart

- Buy Bosch ICON Blades on Advance Auto Parts

You can click the links above to go directly to the purchase page.

Frequently Asked Questions

What is the ideal mileage for Freightliner preventive maintenance?

Most experts recommend every 15,000 miles for basic checks and up to 60,000 miles for more intensive inspections. Always refer to the vehicle’s service manual.

Can I perform Freightliner maintenance myself?

Basic maintenance like oil changes and filter replacements can be DIY. However, complex diagnostics or electrical issues should be handled by certified mechanics.

What happens if I skip preventive maintenance?

Skipping scheduled maintenance can lead to engine wear, poor fuel economy, higher emissions, and expensive repairs. It also shortens the truck’s lifespan significantly.